Content:

Beekeeping is a complex activity that originated in ancient times. As mankind developed, so the process of collecting honey developed and improved. One of the options for hives, which are used by modern beekeepers - a hive lounger. Its peculiarity is the development of the bee colony in the horizontal plane.

The inner space of the case is filled with bees, and the store specially placed above it is filled with frames that are filled with honey. A popular type is the 16-frame bee hive, designed for one bee colony, and 24-frame, in which up to two colonies can be accommodated.

Beehive lounger for 24 frames: correct drawing

A 24-frame beehive plank bed is common among beekeepers, both amateur and professional. It does not require constant care and supervision, there is enough space for the bees, however, when the family grows, it is necessary to make additional ventilation holes.

Its production is based on boards made from fruit trees or other species, such as birch or ash. Humidity should be no more than 15%.

It is best to make a hive lounger for 24 frames according to the drawings and dimensions, which will be described below.

The preparatory stage of manufacturing includes cutting blanks according to a drawing, cutting holes, creating a tap hole. The assembly stage begins with the installation of the bottom - it can be removable and built-in. The body and other elements are assembled from shields 35 mm thick, for two end (front and rear) strips. For a hive of a sunbed for 24 frames, it is necessary to make a slot inside the case, along the front walls.

It is needed to mount the partition, thereby dividing the space into two compartments. Round holes are cut from the main facade. As soon as the bee colony has grown, two stores for collecting honey are placed in the nesting section. Extension boards with ventilation openings are installed above the store, on which the insulation will then be laid. The roof is flat and consists of a removable box of wooden panels.

Once the building is fully assembled, it needs to be painted and the carrying handles attached.

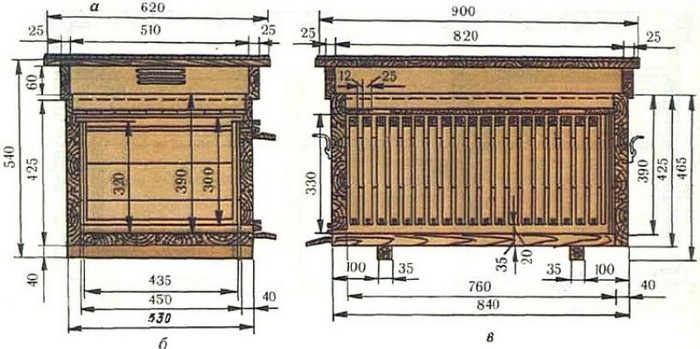

The dimensions of the frame of the beehive lounger for 24 frames is 419 × 25 × 145 mm, the overall dimensions are 935 mm long, 585 mm wide and 635 mm high. Despite its large dimensions, it is not difficult to install it on the ground. The advantage is its large size, it takes less time to spend on cleaning and caring for the hive, you can place up to two bee colonies, enough space for their full development and productive work in collecting honey.

Beehive lounger for 16 frames

A perfect solution for one bee colony will be a hive lounger with 16 frames. The versatile volume makes it possible to grow strong colonies. Compact in size, convenient and easy to use, so it is popular with beginners in beekeeping.

Dimensions of the structure

Dimensions, along the inner contour of the walls, are: width 450 mm, length 615 mm and height 330-390 mm - varies from the number of superstructure stores.

After the bottom and the nesting compartment with the entrance have been assembled, it is necessary to make and install the folds. They are used to attach frames to the inside of the hive stores. They are arranged on the front and back walls. The section of each fold is 11 × 20 mm. Store extensions are mounted on pre-built quarters on the outside of the case, in the upper parts of the board. They are made of wooden planks 3 cm thick. The main dimensions of length and width correspond to the overall dimensions of the body on which it will be placed, but the height is taken as 145 mm or 165 mm.

The roof liner walls are made of wooden panels 25 mm thick, in the corners they are fixed with nails.

The roof has a flat structure and is assembled from planks with a section of 90x15 mm, fastened to each other by means of quarters, nails and glue. It covers the outer walls of the hive and protrudes 2 cm from their plane. Ventilation outlets are arranged in the lateral sides.

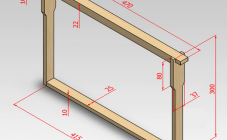

Frames with permanent dividers are used in the nest and shop sections. The socket part is made with a size of 435x300 mm, and the store part with dimensions of 435x145 mm.

Varieties and benefits of other types of hives

In beekeeping, in addition to the classic lounger hive, the following varieties are distinguished:

- Alpine- it has a compact design, where the development of the bee colony takes place in the vertical direction. The inner part, with a place for bees, is made in the form of a hollow. There are no partitions, ventilation is carried out naturally, through the notch;

- Cassette type... Its peculiarity consists in thin partitions, which provide bees with a favorable microclimate. The main goal is to create conditions that reduce insect disease, so the walls are coated with wax;

- Ruta - it is used only in the southern regions from a special design that requires constant rearrangement of stores, which leads to heat loss;

- Ukrainian lounger suitable for beginners, easy to use. Simple construction and insulated side walls. Bees honey well;

- Dadanovsky hive is the most popular model among beekeepers. Its scheme is compact, designed for 12-16 frames; in winter, bees are kept in the nesting department.

The scheme for making a lounger hive, what are its features and advantages over other hives

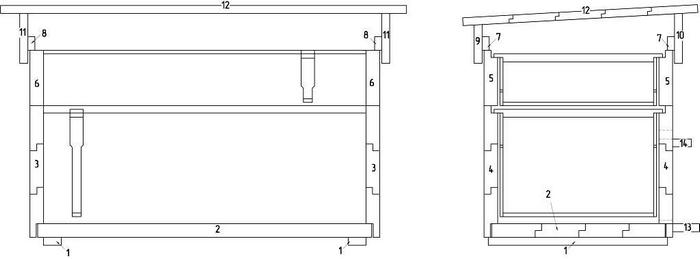

The lounger hive is made according to drawings and is a prefabricated panel structure. It consists of six main elements - the bottom, the body - the nest compartment, magazines, a liner and a removable roof.

The main feature of an ordinary sunbed hive is a frame module, the overall dimensions of the building depend on it. It is necessary to determine their number and build according to the drawings, with the specified parameters of the length of the walls, bottom, roof, because the ratio of these indicators for hives of sun loungers for 16 or 24 frames will be individual.

There are three ways to install a bee bed in a hive:

- Do it yourself according to ready-made drawings for the required number of frames. This process is laborious, you need to measure and cut the boards, and then fasten them using screws, nails, corners and special tools;

- Order a disassembled hive-lounger, and build it directly on the site. The most common and budget option;

- Order a ready-to-use bee house assembled at the factory by experienced specialists. Refers to an expensive option, since assembly and transportation are additionally paid.

Advantages of the lounger hive over other models:

- no need to rearrange the overall structure and honey extensions;

- layering can be done next to the main bee family;

- ease of use of the framework;

- good development of bees in sunbeds and simple implementation of measures to warm the hive.

Maintenance and development of bees in sun loungers hives

Keeping bees in sunbeds is not a problem. There are 5 rules that will allow them to develop optimally, creating good families, bringing a high yield of honey.

- In early April, clean the lounger;

- In hives for 24 frames, it is necessary to create two families in May by installing a partition - a diaphragm;

- In mid-May, leave only uterine and forage frames in the nests. Install dividing bars between the branch and the swarm, and a brood frame. Remove the barrier between family and swarm. Add frames up to 10 pieces;

- In July, the lounger hive store is filled with the maximum number of frames;

- Reducing the interference of the human factor in the manufacturing process will have a beneficial effect on the quality and volume of the product.

Keeping bees in sun loungers in hives will not cause problems. They are easy to operate and have enough room for development.