Content:

A motor-cultivator is a type of garden equipment designed to facilitate the work of summer residents. With it, you can effortlessly dig up the beds, loosen the soil and weed weeds throughout the season. As a rule, this garden equipment works on a gasoline engine, and plows the ground to different depths - from 8 to 25 cm. But it so happens that it breaks down.

Main spare parts for motor cultivators

Each motor-cultivator of a particular brand has its own vulnerability, because of which the equipment stops working.

Mole

One of the most common domestic cultivators is the Mole. Its equipment consists of a clutch handle, throttle adjustment knob, and carburetor choke control. The basic equipment of the Mole also includes electronic ignition, a fuel tank (minimum volume of 1.8 liters), an air filter, a main engine for 6000 rpm, a gearbox and wheels for the Mole cultivator.

Cultivator Mantis: spare parts

The Mantis cultivator is produced in the USA, Pennsylvania. They began to complete this technique in 1980, and for almost 40 years it has gained great popularity in different countries of the world. As of now, the number of copies released from the assembly line has exceeded 1 million, production continues to this day. The device is lightweight, which makes it much easier to transport it over long distances not only in your own car, but also by public transport. In addition, due to the light weight, even a fragile woman can control the technique.

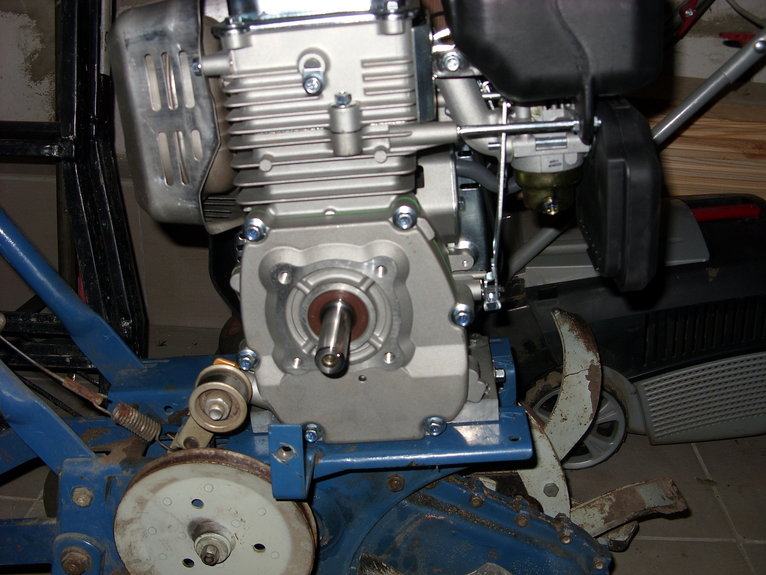

The device of the walk-behind tractor is quite typical. It has several main working nodes. This is a frame structure, directly on which the engine for the cultivator is located. It should be noted that the cultivator's engine can run not only on gasoline, but also on electricity. It also provides a starter type start, a handle (there is a power button and a clutch drive on it), a bracket (due to which the attachment is held). Of particular note is the worm gearbox. Its main task is to reduce the negative effects on the motor. If pebbles suddenly fall between the cutters, then this element will automatically switch the work to idle mode, which will remove stones and protect the unit from breakage.

Hyundai

Closes the top three of the most popular motoblocks - a cultivator from the Korean manufacturer Hyundai. It consists of a powerful engine.

Push

The cultivator of the shock-absorbing group of Nadavi - the motor-cultivator Mobile K MKM-Mini deserves special attention. This is a motor cultivator with a power take-off shaft, which also regulates the operation of the engine during various malfunctions.

What spare parts for cultivators and motoblocks should be stocked

Without exception, all equipment breaks down sooner or later. However, it is not always necessary to run to the service center at the first problem and pay a lot of money for the repair of a simple breakdown.

A farmer who has a walk-behind tractor should have some spare parts in stock. If necessary, they can be replaced at home, without contacting specialists.

In spring and autumn, when every day counts, there is no time to carry equipment to service centers.That is why experts recommend having some spare parts in stock. The additional ones will never be superfluous: a muffler, a gear, a pressure roller, a crankshaft, a reducer, O-rings, sets of bolts for fastening, shafts, wheels for a Mole cultivator, a clutch handle for a cultivator, a worm gearbox for a Robi cultivator, and a starter for a cultivator. Before the start of the season, it is better to check if all these parts are available, and if not, then immediately purchase them.

What breakdowns can you fix yourself

When working with this garden equipment, a large load goes to the motor. Therefore, as a rule, the bulk of the problems are with the engine. It is easy to diagnose engine problems as it starts to run slowly and loses power. In case of such a problem, you need to check:

- whether the engine is warmed up (especially if the equipment is used in the cold season);

- whether there is contamination in the air filter;

- whether the gasoline used is of good quality;

- whether the ignition system is in good condition;

- whether residues of combustion products have fallen into the muffler;

- whether the carburetor is dirty;

- attention to the piston elements, they must be intact.

However, it happens that the engine does not start at all. In this case, you need to look at its position. The engine must be properly secured to the frame. It is also worth inspecting whether there is enough gasoline in the tank and whether there is a blockage on its cap.

Often, repairing this garden technique at home involves cleaning the carburetor. The first step is to completely disassemble the assembly. Then it is cleaned, but they do it all strictly according to the instructions from the manufacturer. The essence of these works is to ensure that the float is evenly immersed. Most often, for this you need to eliminate the deformation of the bracket. It is with the help of this element that the float is fixed to the piston system.

Adjustment of the float immersion can be performed in an open or closed needle valve. To align the bracket, you need to take a regular screwdriver.

After the deformation of the float is eliminated, it is worthwhile to adjust the valves of the walk-behind tractor. It is a good idea to first check if each one fits snugly. This action will help restore all functions of the carburetor, as well as return the required rate of fuel consumed by it.

And another frequent failure of the engine is a malfunction of the fuel pump. It is he who supplies fuel to the carburetor.

The pump can be faulty in three cases:

- the fuel supply to the engine nozzles is interrupted;

- due to mechanical wear, the fuel began to leak;

- a strange sound appeared during the operation of the equipment.

In this case, experts advise to disassemble the pump and inspect it carefully. Most often, a failure occurs due to the fact that the pump is dirty inside. It is cleaned and re-collected.

What breakdowns do you need to contact service

Not in all cases, you can repair the walk-behind tractor yourself. Below are a number of problems in which it is recommended to hand over the equipment to the service center for repair:

- you need a complete repair of the electric motor or a complete replacement of the motor for the cultivator;

- to replace the crankshaft, their bearings and oil seals;

- if the old one knocks and a new gearbox is required for the cultivator;

- replace the carburetor, cultivator belt;

- change control elements, cultivator stand;

- repair the valve block, fuel tank.

In addition, any technique needs timely maintenance and proper care. That is why experts recommend that once every few years bring a motor cultivator to a service center for preventive diagnostics. Thanks to this procedure, the walk-behind tractor will not only work well, but at the same time, its service life will increase.